northener51

-

Posts

19 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Shop

Events

Downloads

Posts posted by northener51

-

-

Sorry man grammar error. Drivers door wiring loom and locking motor was what I was supposed to say!

-

Do you have the drivers front wiring loom and door loom available? For my vRS. Does your car have central locking heating wing mirrors electric Windows etc

-

Thank you. I have arranged another loom after noticing your post. If the other item I have arranged doesn't come to fruition I'll get back in touch

-

Do you have the drivers door wiring loom with all the pins intact on the connecting block? If so how much posted please

-

Managed over the past few weeks to get my front drivers bearing sorted. I managed to press out the old damaged bearing but whilst pressing in the new one I damaged it. I put it all back together as a temporary measure then when back together I had all the ABS and traction control lights set off. When I pressed out the hub it wasn't in the greatest of condition and was very rusty. Knowing I had to replace the bearing again I ordered a new bearing, hub and speed sensor. I got myself VCDS Lite and a cable for my laptop to diagnose the fault and it showed a sensor failure to some extent

I got going and noted on removing the wheel that the speed sensor wiring had been damaged. I then noticed when I refitted the hub to the suspension strut, the strut had turned moving everything around and caused the wheel to rub against the speed sensor wiring breaking it, hence the warning lights setting off. What I did do is replace the whole lot anyway to ensure it all was working, and as a temporary measure soldered and replaced some of the damaged wiring til I could replace that part of the loom

Removed the hub casing by taking out the driveshaft, track rod end, lower ball joint, brake disc and calliper. Then removed the hub bolt and then placed a small chisel in the groove and then using with my persuasion tool knocked the hub casing off

I removed the speed sensor the best I could then burnt out the rest of the material

I then pressed the hub out, removed the circlip and then pressed the bearing out. I cleaned the area where the bearing was and then pressed in the new bearing. I used some CV grease to coat the inside of the hub casing before pressing the bearing in

I then used the casing from the old bearing as a spacer to then press the new bearing home fully

I the greased the area where the circlip would sit

And then put the circlip in using a pair of pliers. I then tapped the circlip into the groove using a screwdriver and a persuasion tool to ensure it sat in the groove

I then fitted my new speed sensor and pressed in my new hub

And re-fitted the hub carrier back in the car. This is the sort of chisel I use to fit the hub carrier back onto the suspension strut. Splits the hub carrier a few mm so it makes it a bit easier to slide on. This is where you need to make sure your suspension strut is positioned correctly before you to tighten everything up!

As you can see from the last photo the suspension strut is positioned wrong and the strut had twisted anti clockwise. All I needed to do once I had the hub in place and everything bolted back together, is to insert the chisel back into the groove and then twist the strut into its correct place. I had put the wheel back on and one of the supports for the wiring was rubbing against the tyre. Lesson learned. I have also fixed my drivers seat back support and will show you how I did that in a later update

-

Is the drivers door wiring loom still available as well as the drivers door lock?

-

Hi there

Do you have the front drivers door wiring loom?

-

Hi there

Looking for the drivers door wiring loom if you have it?

-

Looking for the price on the drivers door wiring loom complete please

-

Long time with no update mainly due to not having time to get my hands dirty. Basically I gathered a load of parts to do a front end suspension refresh/rebuild. The front end was knocking and crashing on the lightest of bumps and from the previous update the roll bar bushes had been changed but not well as the roll bar link was hitting an inter cooler pipe.

I bought a full Superflex front end bush kit including the gearbox and steering column bushes, new track rod ends, lower ball joints and the anti roll bar links. I also had a brand new drivers side driveshaft as the boot had split and on inspection the shaft had seen some better days. As it cost only £55 complete without exchange seemed like a no brainer just to remove and replace.

Set off on stripping it down and rebuilding. On getting the track rod ends off the steering arm s were in really bad shape. I used my metal brush to remove the rust and the threads just disappeared. I managed to get it apart and then after hours of trying to make the front suspension arm bushes fit realised I got send the wrong bush. Bag was labelled with the correct part number with the wrong part number inside.

Managed to bodge the bush to get it to fit then get the car back together to get it back on the ground so I could get the right part in.

Got the right part received and got back on with the rebuild. I managed to get a new set of track rod arms (axial rods some people might call them) and set about stripping and rebuilding again.

After doing a bit of reading about the track rod arms I ordered a 32mm crows foot to help get the arms off. I got a 6 sided foot and once I got the arms realised that the arms were actually 8 sided. The foot wouldn't fit. Didn't matter anyway as there is plenty of access to the arm once the steering is manipulated to use a plumbers wench or mole grips to get the arm off and tighten on replacement. This will only be case of you have the front suspension stripped away. If you haven't access is very limited and you will need an 8 sided crows foot to get it removed.

I got all the bushes pressed into the front and rear of the suspension arm with a new lower ball joint fitted as well.

And a new track rod end was fitted as well. I also poly bushes the roll bar bushes and managed to get a new set of brackets for the bush and a bolt. These bushes are 19mm in diameter and fit perfectly. On removing the old bushes there was a small plastic piece of casing left from the previous bushes on the roll bar. I also moved the roll bar over a few mm to make more space for the drop link

And also the new driveshaft and roll bar drop link. One thing to note on the drop link is that on one of the ball joints the thread is shorter probably to compensate for missing the intercooler pipes so worth looking before fitting. Fitted the shorter thread to the roll bar to help with clearance for the intercooler pipes.

I managed to fit the steering rack polybush whilst in situ and the subframe did not need to be dropped down to help. if you have the car high enough on axle stands and the front suspension stripped away there is plenty of access to replace this bush with ease.

The drivers side rear arm bush literally fell out as I removed the arm. This bush was so bad the metal casing it was in had slightly worn away as it had been rubbing against the subframe. No lasting damage and the arm was fine. All fitted both sides and the drive is fantastic. Only thing now is I must have damaged the wheel bearing removing the driveshaft as it is making lots of noise so that's my next job. I got limited for time so I didn't manage to get gearbox bushes in either so that will hopefully all be done before winter sets in. Reason I might have damaged the wheel bearing is when I bodged it back together to wait for the new bush I didn't have the outer CV in the bearing torqued in.

All in I'm enjoying the car and it came apart very nicely was just time consuming getting it together. If I didn't have the bush or the track rod arms its a days work 6-10 hours depending how competent you are. I did have to burn out the front lower arm bush and for the sake of it I would order the new track rod arms of your planning at work on the track rod ends.

-

Andy;

That thread you have posted answers the question perfectly thanks

-

Hello there;

I have a Mk1 Octavia RS with some front end knocking of which I am going to overhaul the bushes on the front suspension. When looking around the front end I noticed that my front subframe bushes are very tired

As you can see they are splitting and need replacing. Now on limited info and reading it appears the standard bush is a one piece which will need pressing in which will be an absolute ball ache of a job. However on reading it appears that the Audi TT two piece subframe bushes may fit

These are the part numbers I have found for these

Upper Mounting – 8N0199282C x2

Lower Mounting – 8N0199282D x2

Question is will these bushes fit and do I have the right part numbers? These bushes will make my job so much easier and could be done with the subframe in situ in theory. I can't seem to find any polybush equivalent so any other advice suggestions would be appreciated

Pete

-

1

1

-

-

Hello everyone

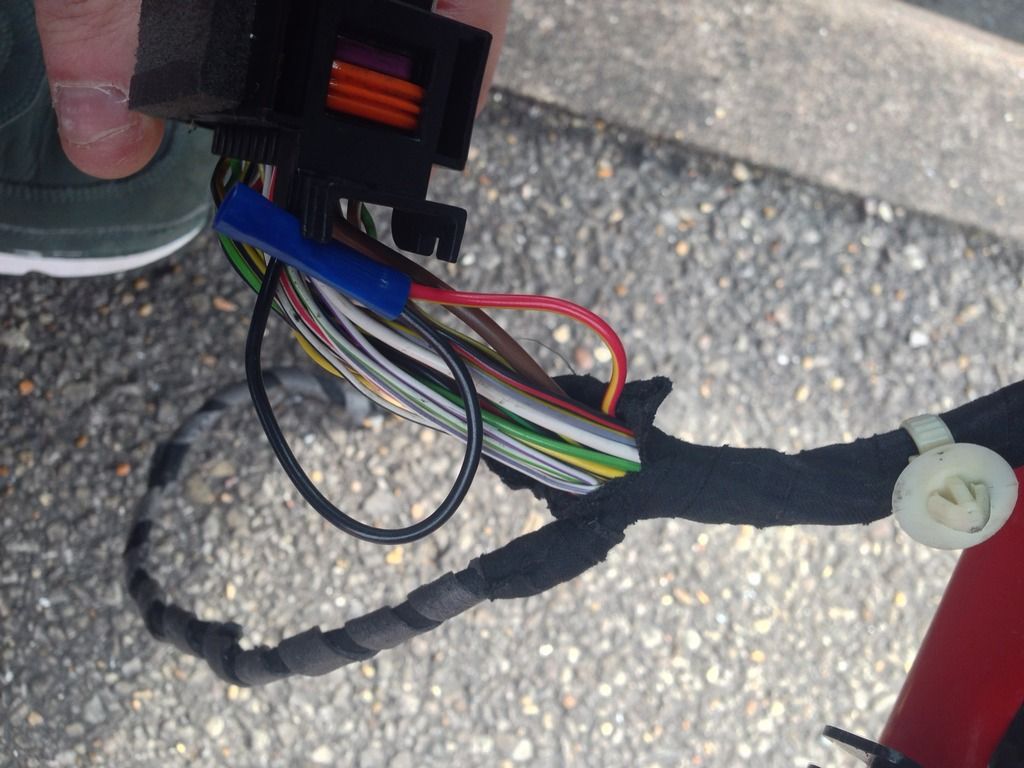

Today had a look inside my drivers door to try and sort out my intermittent locking fault. Got the doorcard off and found the previous owner had nicely bodged the connector block and one wire in particular as shown below

It's a red/yellow wire which fits into the bottom of the control box on the bottom of the window motor. Can anyone tell me what this wire in particular controls/powers? I know it'll mean a new door loom long term so anyone got one at decent money?

Don't worry about the moisture. That's my contact cleaner! Doubt it's the wiring and think it's the actual motor dying from my locking issues, as even before cleaning the contacts they were very clean

-

Update time

Been gathering a lot of parts to do a major service over the past month as the car was due

As I had literally got all the parts to do the service I was driving the car to work and opened the car up to 5k in 2nd just to stretch its legs and then heard a massive bang from underneath the car, then queue the car exhaust note sounding like a tractor! I had a good look underneath and found that an exhaust bracket had failed. So after work drove the car home sounding like a tractor and then got it to my workshop/garage with a pit. Prior to this I had bought a new centre section exhaust as the one fitted didn't look too clever and once underneath found this

And to my amazement the centre box was still the original but it had suffered over the 10 years and definitely needed replacing as it had rusted quite badly on a join and as I poked at it I broke through. Just goes to sow how good the parts fitted from VAG are from factory that exhaust parts were just failing after all this time

Plus the next clamp wasn't too clever either

When I went to my parts place they supplied me with a new centre section and two circular clamps. What I didn't realise or could see at the time of looking underneath the car is that the original clamps had a sleeve underneath to attach the two parts of the exhaust together. The parts place only supplied two round clamps and no sleeve. By this point I had dissembled the centre section! The sleeve connecting the turbo downpipe to the centre section was in great condition. The rust shown was all from the clamps and once cleaned up was perfectly re-useable. I simply used the sleeve and the two new exhaust clamps and it sealed ok.

The other sleeve from the centre section to back box on the other hand was rotten. Had no choice but to re-use it in the short term with two new clamps to get me to work. The exhaust did blow on this section but not massively so I ordered a sleeve and clamp system from e-bay and that was fitted when I serviced the car. The clamps with the sleeve are a PITA to fit so I used traditional clamps with the new sleeve and now all is well.

If the back box goes I will consider getting a full stainless system. Haven't got the money at the moment hence the economic repair and prioritising the service. Think sorting this issue was around £55. So drove the car to work for a few days then performed a major service replacing the following

Sump removal + Oil and filter change

Full brake fluid change including the clutch slave

Gearbox oil change

Air and Pollen filter change

Clean throttle body and replace throttle body gasket

Before buying the car read heavily about oil pickup issues being the main engine killer. Although this car is low mileage (67k) and has been serviced more or less every 12 months around 6-7k I wanted piece of mind. As the sump appeared to be very easy to remove I got to it. After a good few hours I got the sump off. It took longer than planned as I hadn't done it before and I had a real issue accessing two of the hard to access bolts on the gearbox side. Managed to get to them just about with a 1/4 extension, short 10mm socket and then to remove the bolt fully used a long Allen key. Knowing what I know now I'd have the job done quicker but as always hindsight is a wonderful thing. Removal of the sump after getting these bolts out is pretty easy, as its just a case of removing all of the 10mm sump bolts, the two bolts securing the turbo oil down pipe, three bolts securing the gearbox to the sump and the wiring connector for a sensor. Here were the results

The pickup pipe had nothing inside it all and was super clean. Was a bit annoyed I had took the sump off at this point but then after properly assessing the inside of the sump I'm glad I did

Three was some dirt in the sump, oil was staring to congeal and become 'gloopy' and if left longer probably would have started to break away and the pick up pipe would have become blocked. So with some elbow grease and a lot a degreaser I cleaned the sump out

Much better. Sump was re-fitted using a high temp RTV sealant and then left for 48 hours. This was to give the sealant time to properly cure before adding oil. I also fitted a new gasket to the oil downpipe from the Turbo on replacing the sump. All the bolts for the sump were torqued down to stop any leaks. Reason for waiting 24 hours is that the sealant I had recommended waiting 24 hours at 20c for the sealant to properly cure before introducing any fluids. I gave it 48 just to make sure.

At this point I performed the rest of the service. Found the slam panel plastics underneath the front windscreen a PITA to remove to replace the pollen filter. Managed to crack the windscreen like an idiot. The screen was on its last legs as it had two chips which hadn't been repaired and really needed replacing anyway. That's already been booked in and will be happening next week. Not the expense I needed but knew was coming anyway. Pollen filter did need replacing though

And just a few quick photos of the clutch slave cylinder for the fluid change. It is situated underneath the air box

Removal of the air box is a few 10mm bolts and removing the jubilee clip securing the air box to the induction system. One at the top neat the suspension strut and one is hidden at the back of the battery box which you an see the threaded hole for.

I also removed the 10mm bolt securing the pipe which leads out of the inside of the passenger wing. Just gives you that extra bit of movement to get the whole air box out

After completing this I decided to look underneath to see why I was getting a lot of groaning and banging around from the front end whilst driving. Suspected roll bar due to this being one of the weak points on the car. I grabbed hold of the bar itself and the drop links and apart from some real minor play in the passenger side drop link it was solid. Bushes appear to have been replaced at some point as they don't have any sleeves. But then noticed this

Appears that when the bushes were replaced as well as the drop links at the same time, the ARB was moved over more towards the passenger side of the car. I measured the roll bar from the bush out towards the where the roll bar bended on each side of the car and the ARB is about 2cm over to the left side of the car. What this has done is pull the drop link on the drivers side of the car inwards and has caused it to hit the intercooler pipe next to it. Appears it hasn't done this for a while as the nut/both have rusted over and there is no clean mark on the bolt anymore. However would cause aright racket when it did hit it.

However it appears that the radiator is more of an issue than the roll bar. The top of the radiator is solid but the bottom is free to move a good 2-3cm forwards then backwards. I sat in the car and rocked in the drivers side violently and you can hear the radiator moving and knocking about. So I have ordered and collected some new radiator bushes and will look to fit them in the near future. I have some new roll bar bushes as well so I might as well replace the bushes and drop links and move the bar more over to the drivers side of the car to stop the bar knocking the intercooler piping. Replace the radiator bushes then move on to the final other issues.

Lumbar support on the drivers seat is not working and both my drivers side doors are not locking properly intermittently. So door cards off and the usual contact cleaning/protecting is needed. Motors from e-bay appear to be cheap so I might just replace them at the same time for peace of mind. Once all the issues are sorted can look to sort out a few cosmetic issues in the Summer once I have my classics on the road. After sorting out the service and waiting 48 hours filled the car with all the oils it needed and then set off. All appears well after service. I would have taken some pictures of the throttle body but it wasn't worth it as there wasn't much dirt in there. Also on checking the pipes from the intercooler there wasn't much oil in there either. On advice from other guides I did not remove the multi plug! It was given a clean anyway and gasket replaced for peace of mind.

Til then happy motoring people!

-

1

1

-

-

Sorry for the slow updates but my previous laptop decided to die so I had to save up a little bit to get a new one. Getting all of old data off my previous laptop has been a bit of a mare. However I am back and can update you. Beginning of December decided to tackle the rear brakes as they were in a poor state and needed a major overhaul

Before I even started I had ordered a new set of pads, discs and new calliper carriers and guides. Due to the condition of the rear brake callipers themselves it was clear at some point they had been replaced as they looked relatively new. I got my new carriers fairly cheap but they needed painting

After finding though the searches on here the potential paint got it ordered and then got the callipers painted in the nice green

The paint came in a tin so needed to be applied with a brush. Took a few coats and 24 hours to property dry before I could get on with the rebuild. The callipers came off easy and one of the bolts holding the carrier to the rear hub was a bit of a stubborn sod and needed some heat but finally got the system dismantled. How the previous owner or even a mechanic thought these were in a condition to be on a car is beyond me....

Front of the disc

Rear of the disc

What was left of the pads

And the condition of the carriers

Was a bit horrified after seeing the discs and pads. I had to mallet out the pads as they were stuck on the carrier guides and whoever replaced the callipers at some point really cut some corners here which freaked me out a bit. If the had replaced the discs and pads without the carriers I could understand. The carriers were working and serviceable just cosmetically tatty, and the guides just needed a good clean and resitting on the carrier. The pads would have been stuck to the disc each time the pedal was depressed and wouldn't have released due to the way they were stuck. Hopefully the rest of the car is not like this!

So after getting rid of the bad fitted the new. A good clean and copper grease of the hub (discs had stuck to the hub) and place on the disc, good amount of copper grease on the carrier bolts and a smear of clear grease on the new carrier guides (pads had were stuck solid on the old carrier guides and were not moving!!) then a bit of copper grease on the back of the pads and then re-fitted the calliper over the pads. One good thing about the system was that the callipers were in good condition. All the dust covers were intact and not split, and the pistons wound back very nicely. And then voila!

Paint match is off but it looks ok without the flash of my camera so I'm not too fussed. And after finishing the other side and taking the car out I no longer have pedal wobble from a warped disc which is very nice to have!

Next task is a major service of all the oils that I can then have a look around the front end for the knocking I'm getting. Guessing it is anti roll bar but going to get underneath and have a proper look around first

-

Yeah I got a thread over on RoverTech for the Rover

-

Here's my project thread for my Octavia vRS

There are many reasons why I bought this car even though I have two already!

Firstly a needed a more practical car than my previous daily

My Rover Coupe. 197bhp 2 litre Turbo. All the added extras Rover could throw at it. My love for four years and had more or less a minor restoration. Bought with only 27k in the clock from new and now has only 55k.

I have recently bought a house and got a dog and the Coupe has no boot for a dog or is practical really to carry the dog either. As the Coupe is getting older and rare it was time to retire it and use as a classic like my other car

My MG BGT. Both cars are really future investments. BGT has had a full restoration four years ago again majority of it done by myself other than the paintwork.

Anyway back to the vRS. Needed a more modern car to carry the dog and everything else associated with owning a house. Trips to B&Q and generally 'growing up'. Unfortunately the kid inside of me cannot be rid of so I needed a car with performance as well. Used to drive these cars regularly as a Police Officer as a response car on 999 calls and loved their power band and practicality we used them for. They are sorely missed and truly the best car I have driven daily. Had to have one for myself.

So found this fella in Bolton

Full service history, 12 months MOT, 4 years left on the cambelt, 4 brand new winter Continental tyres and really no knocks whatsoever. Winner for me. Has the typical jack up point damage on the front unfortunately but it's not too severe and it desperately needs new rear pads and disks. But I'm not shy of getting my hands dirty so didn't put me off. What it did need desperately was a damn good clean inside and out

Never owned a Skoda/Audi/VW group car before and after a few searches on here found the front seats were so easy to remove I decided against sending it to a valet company to do the job. Rented a rug doctor from the local supermarket and got it to it myself

Seats front/rear removed and here is the state of it beforehand

It was proper grime. Hasn't been properly valeted inside since new I think. So with the Rug Doctor Carpet Solution in the machine, Autoglym Interior Shampoo and Vanish Carpet Stain Remover worked it into the carpets, seats and door card fabrics with a stiff brush and plenty of elbow grease. I put all of the carpet mats in the washing machine for a good clean. Hovered it all out using the Rug Doctor and the results were fantastic. I also wiped down the whole interior spraying Autoglym Vinyl and Rubber Care, a bit of Dettol Surface Cleaner on the dashboard and plastics and gave that a good wipe down. The leather on the seats were scrubbed using Autoglym Leather Cleaner and then the fabric was given the same treatment as the carpet. A bit of Autoglym Autofresh to give it some long lasting freshness and the results were brilliant

And all back together

And this is the grime that come out of the carpet

And off the interior plastics etc

I've given the whole car a clay bar (took three hours due to tar everywhere) a good wash and polish as well but due to the bad weather haven't really got any photos of that yet. I‘ve done all the door and boot shuts, fuel cap and other awkward areas as again hadn’t been done ever. Next job is to tackle the rear brakes (shocking images to come) and there is a constant knock on the front end that needs investigating. The way it’s knocking sounds anti roll bar but after reading the common faults could well be the radiator loose as well. Will come back with more soon.

My first post was a bit all over the place and had missing pictures. So sorry if you have seen this before but wanted it to be right.

-

1

1

-

-

Hi there all

Bought myself a Mk1 Octavia vRS as a new daily driver. Had been driving a Rover 220 Turbo Coupe as my daily but as I moved into a house and got a dog wasn't the most practical car for dog carrying!

So got this beast

Will post up a progress thread somewhere once I've sorted out where to put the thread!

Will need some advice on a few issues I have with the car soon so fingers crossed you can help!

Thanks

Pete

Various mk1 Octavia vRS sundries

in Parts For Sale

Posted

Is there a drivers door wiring loom in there somewhere?