Toonarf

Members-

Posts

27 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Gallery

Shop

Events

Downloads

Everything posted by Toonarf

-

Hi All I am still working on the car, just lacking both the time and interesting pictures to post. I lifted the car off the engine and gearbox last Saturday morning. I rested the engine and gearbox on a trolley and wheeled the assembly out with the car lifted, Simples…….. There a couple of photos of the engine bay with nearly everything removed to allow the under bonnet area to be painted at the same time as the body which is happening next week, I am waiting for the nod from the painter to deliver it to him. The forth picture is of H49 and A13 SKO at restoration HQ. The ex works car, LYL 5X, is in dry storage. I will be repairing the engine whist the shell is away being painted and I will hopefully take lots of photographs of progress and be able to update regularly. The final picture is of H49 during the 1995 Rallye Bohemia which is the local rally to the Skoda factory in Mladá Boleslav. Tim Green and Peter Johnson came home 4th in class first Skoda Trophy, beating Carl Stevens in A13 FAV by 31 seconds. I was able to drive A13 FAV at Race Retro earlier this year. Thanks for looking David

-

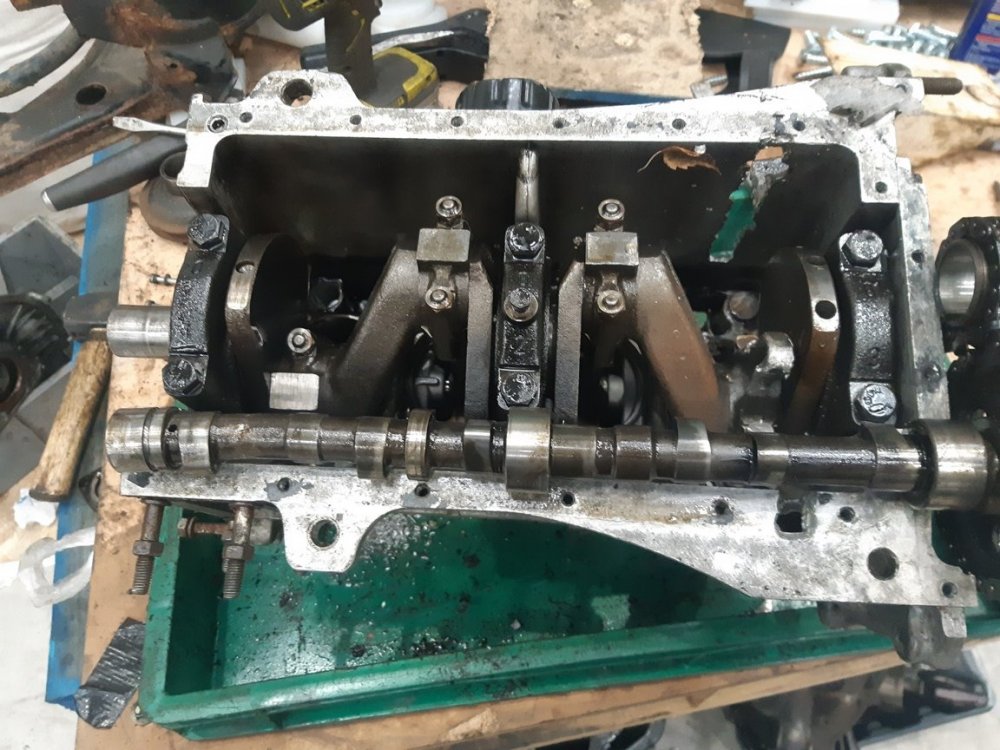

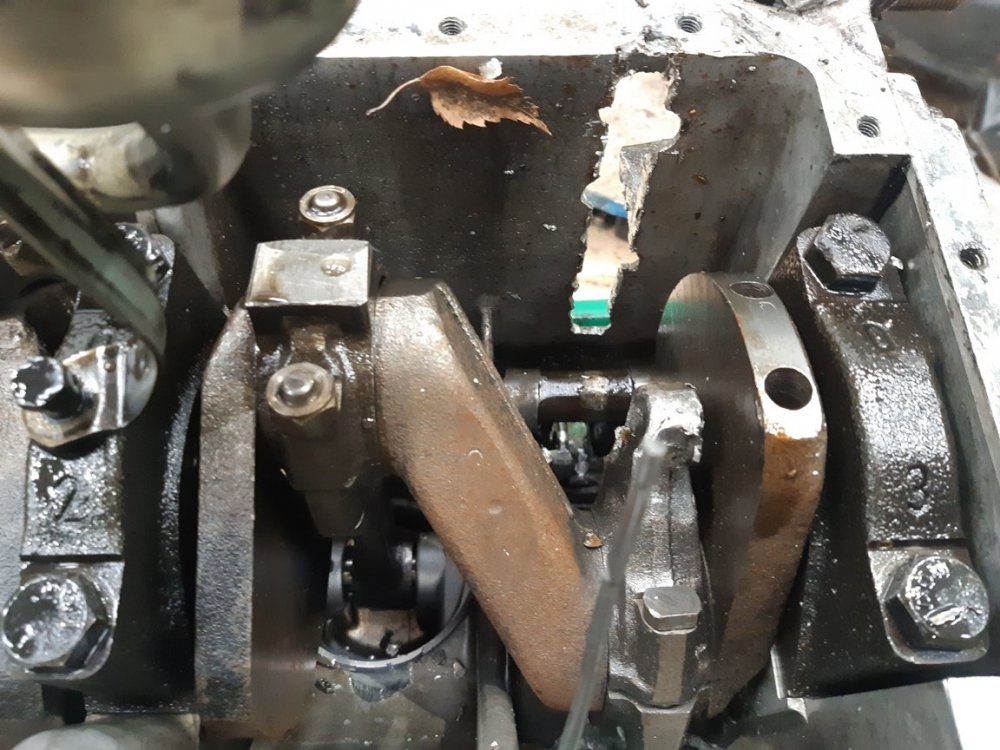

Hi Everyone Firstly apologies for a lack of updates recently, I got busy and couldn't find the time to update. The welding is however almost finished and I will put up the last instalment soon. I am currently removing the engine, it has a high antifreeze content in the sump and a very rattly timing chain. So a quick rebuild and freshen up is called for. So to the reason for this post. You might recall that in early January we had a small road trip to Inverness to collect another ex works Favorit. The car came with a huge spares package including another Favorit rally car. Last weekend had been pencilled in for the return trip the first picture shows the start of the trip home, we took the picture then before the snow got worse.....which it did. The car as shown in the picture contained 5 gear boxes and 2 engines along with a large pile of spares hence the lowered stance. The second picture is back in Lancashire after a quick steam clean to remove some of the green mold. The number A13 SKO had been transferred before we got the car. The last pictures are the stripdown of one of the engines, we knew it had blown up but wanted to hopefully save the head and the cam, it was supposed to be a quick engine. Its certainly light weight now. The head is good and saveable, I fear the cam may have opened its last valve.................... The engine let go on a stage but carried on running for about a mile to the end of the stage. Thanks for looking David

-

Hi Everyone Thanks for all the recent comments both about the build and last weekend, anyway back to welding…….. Tonight I spent butt welding the repair panel that I have made to the front edge of the cille and around the cille end closing panel which I fitted the other night. I will let the photos do the talking. Photo 1 shows the repair panel during manufacture I bent a piece of metal to the profile of the cille and then turned a small flange on what would be the front face. To this small flange I welded a fillet to create the shape shown. It is clamped to my welding trolley which as you can see is re purposed. I found it, phoned the owner who declined to collect it, so I found a use for it. Photo 2 shows the front flange cut down to the correct size after I had cleaned the welds back. Photo 3 shows a trial fit held in place with my new magnets. Photo 4 shows the panel with the excess now cut from the cille side. I find it makes life much easier with parts like this to make parts over size and cut them down, rather than struggling with small parts which are harder to hold , weld, grind etc. Photo 5 is of the part being welded in. I had quickly dressed the vertical weld back to check everything. Photo 6 is with the panel fully fitted and the top triangle tacked in place to mark the position of the captive nut which will hold the bottom of the wing. Photo 7 is of the triangle removed to to fit the captive nut in the centre of the circle. The final photo tonight is with H49 along with H288 XES with its green bumpers. Supposedly A13 FAV is in the background but under its first UK registration number of L910 ORP. The event is the 1994 or 1995 RAC rally. H288 XES is still about as well although it needs a full body rebuild. Thanks for looking and do please comment. David

-

Me too, Jimmy and Russell Brookes slugging it out to be top Brits on all the big rallies in Chevettes Sunbeams and the Opels. Great stuff! Cheers David

-

Hi Everyone An update on H49 later tonight or perhaps tomorrow. In the mean time here is Jimmy McRea giving it large on Saturday or Sunday. and a couple of photos from the weekend of A13 FAV, coincidentally note the names on the wing of the Peugeot car parked behind FAV in parc ferme

-

Hi Everyone No welding this weekend ........I am off to Race Retro https://www.raceretro.com/ supporting Simon Daly with A13 FAV. If anyone is going come over and say hello I will be near the Rally Rides all weekend. Pictures tonight of A13 FAV, first is a Stage start on the 1993 RAC which was the cars last rally as a Works car, and is the livery the car now carries. The second photo is of the car in its trophy guise owned and driven by Carl Stevens. The last picture is at last years Race Retro where the car was on static display. This year we hope to be demonstrating it and using it for rally rides. So a Favorit being used in anger........ Cheers David

-

favorit rally please help

Toonarf replied to Sdp312's topic in Skoda Favorit, Skoda Felicia, Skoda Fun and Skoda Forman

Hi Sdp312 Welcome fellow ex Trophy car owner...... I was tempted to go and look at that car up in Cumbria, its lack of any history that I (we) could find put me off a bit and then the ex works car I have recently bought came up for sale in Inverness so that was bought instead. My project ids here if you are interested. Cheers David -

Thanks Stratosg. They are simple skills that I have picked up over the years. There are far better car rebuilders out there than I am and I stand in awe of thier skills........................... There are a lot of video's on Youtube both professional and amateur which are worth watching, and some not worth watching .....you can learn from them all. I suppose its all relative. The repair I have enjoyed most was the rear arch, that was a satisfying repair. Any car I am interested in always gets the rear arches felt early in any inspection. H49s near side was nasty.......and so much better when I had finished. The rest of the repairs are letting patches into panels that ideally I should replace. If I did that the restoration would take years and so it would be years before I can enjoy using it. The ex works car I have just bought will be completely stripped and rebuilt properly whilst I use H49. I keep the picture below on the wall in the garage it is what I wish & hope I could achieve. Cheers David

-

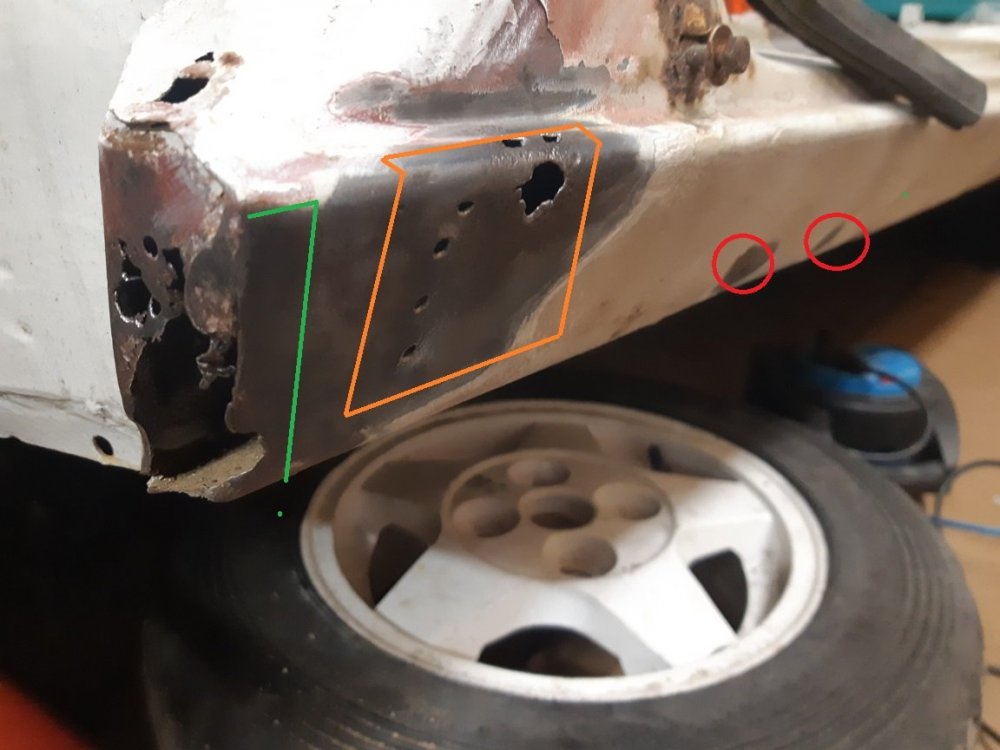

Hi Everyone So I left things last time with the revelation of a frilly cill end at the near side oh joy. The cill is rusty inside and will need copious quantities of waxoyl to preserve it for as long as possible. Back to the repairs, firstly I inserted a patch panel to repair the area bordered in orange on the first picture. I did this to test the weldability of the cill, if it was too thin to weld it was beyond help and I would have to replace it. The second picture shows the repair whilst grinding the welds back. Back to the first picture the 2 areas circled in red are 2 small rot spots I will sort with micro patches, with the end of the cill shown with the green line showing the approximate size of that repair part needed, this repair piece will also need a return to weld to the front face of the cill closing panel referred below. The third picture shows the panel I formed to close the front end of the cill. This was the part that drew my attention to this rot in the first place. The forth picture shows the part being trial fitted. The fifth photo is with the cill closeing panel welded in and trail fitting the wing. The last period photo is a thumbs up from Tim Green. Cheers and thanks for looking. David

-

Thats one way of putting it. The McRea in the photo is actually the late great Colin's Dad Jimmy. Cheers David t

-

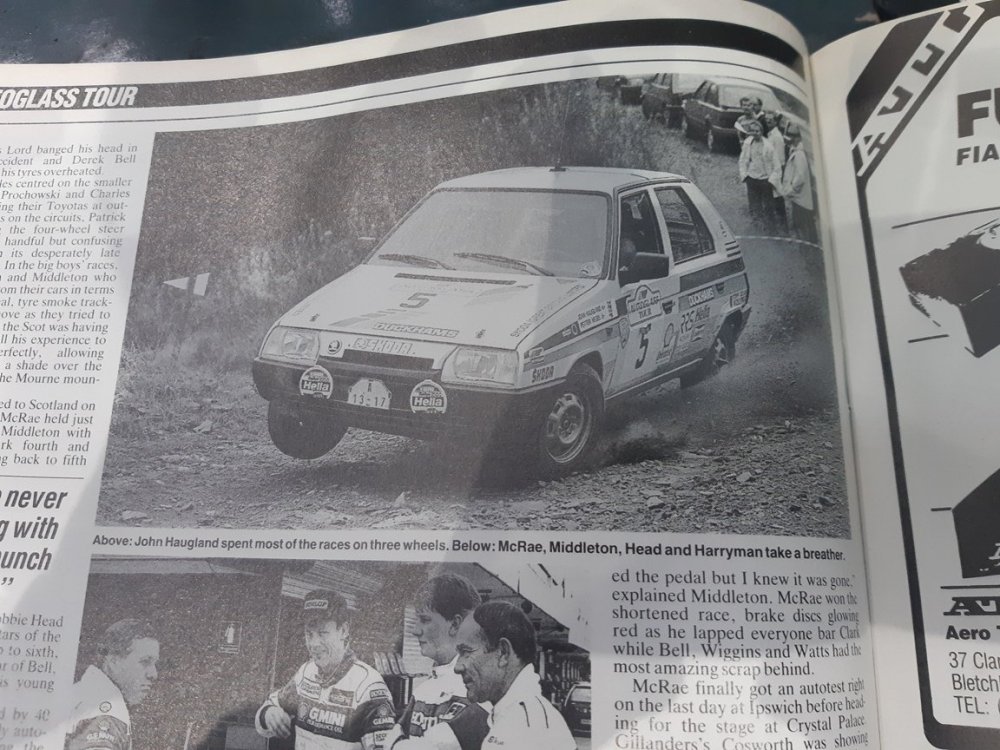

Hi Everyone I am still on with Project H49 but recently and life the cold spell have got in the way and slowed progress, but hopefully I am back on with things. Tonight I broke the out wire wheel out to clear the paint from the front end of the cill, to weld a mudflap mounting bracket. The first picture shows the holes revealed. In the past few weeks I have replaced the petrol and brake pipes and refitted some front calipers that I overhauled. In other news I am now the part owner of another rally Favorit, this time a very early car. It is going to need a full restoration, it needs cills floor pans and rear wheel arches. It also needs a roof because it has had a light roll in its recent past. The windscreen hole appeats to be the wrong shape as well. As is always the case it was local, not!, it required a quick 720 mile round trip to Inverness to collect. The third picture is copied from a 1989 magazine and shows the car with its famous driver. The final photos are from its days competeing in the Trophy after it was sold by Skoda Motorsport to Skoda UK and then onto its first registered owner. It was originally registered as an age related F reg. Thanks for Looking David

-

Hi Ken, thanks for taking the time to reply. As you will have seen in the last restoration photos, about 5 posts back, the welded in captive nut must previously have come loose and which must have been a pig to sort out. When I fully removed the support plate the captive nut was missing. The nut has to be 13mm high to fit tightly under the stiffener and is M10x1.25 which is a metric fine thread and not as readily available. I would prefer to retain the M10 x 1.25 thread to avoid any future complications. Furthermore to enable full welding the replacement fitting would ideally have a flange on the bottom to give access for welding. The hexagon part would also need to be reduced as much as possible again to give more access for welding. These design requirements mean that I need to find someone with a lathe to turn me the part. Hence my statement “I just need to plan and execute the replacement of the missing wishbone mounting nut” Below is a close up picture of the area, the red arrow points to the remaining captive nut, the orange arrows indicate welded areas. Best regards David

-

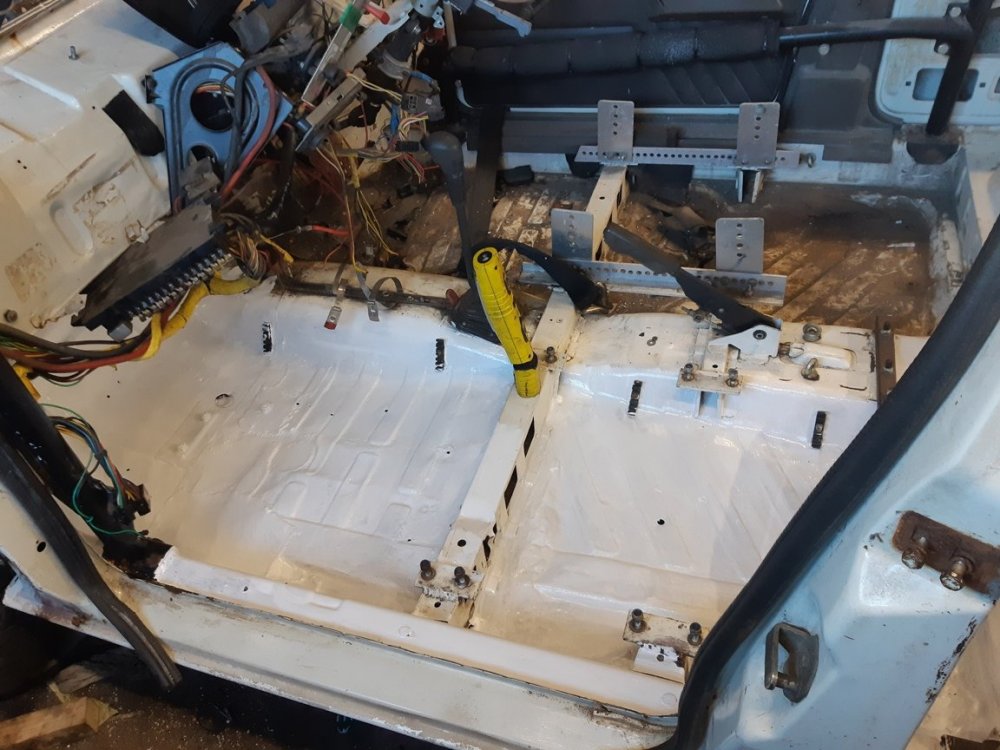

Hi All Thanks for all the positive comments, they help to keep me going when its cold in the garage and the fire in the living room is much more inviting and all I have to look forward to is more welding. Anyway enough feeling sorry for myself I am doing this for fun so I need to smile......... and progress is happening, I am almost finished with the floor pans I just have to plan and execute the replacement of the missing wishbone mounting nut. Then the the floors are finished. It is also going to be painted very soon so good progress. No pictures of the floor pans sorry they are a bit same s@@t different day. The big news is that I have a part share in another Rally Favorit. More news soon but its a bit rough so will need a full restoration before any serious use. Tonight's picture is of H49 in an earlier livery note the early grill. Cheers and thanks for looking. David

-

Thanks Scout. Hi All No updates for a few weeks due to the busy Christmas period. However over the break I was able to get her going drive her out of the garage sweep up underneath, turn her and drive her back in again. So some progress! I had to turn her around because I only have electric plugs down one side of the garage. It was also a boost to finally have a drive of 50 metres as well. The first 2 pictures were taken during turn around day last Thursday. The third picture was taken after I had started on the driver’s floor pan which is the worst so far for corrosion, due to time constraints the replacement floor pan it really needs will have to be fitted later. The red arrow points to a sump guard rear mounting. Green arrow one points to the upper flange of the chassis rail, I cut the metal out to remove some previously badly repaired corrosion. The 2nd arrow points to the foam which has been used to fill the chassis rail presumable to slow down its deformation during rough road rallying. The third arrow points to the circular hole left in the chassis rail during manufacture. The orange arrows point to the captive nuts which hold the rear end of the wishbone. You will notice that one of them is missing. The thread I have discovered is m10 x 1.25 a fine metric. So the next picture shows the same scene with the stiffening plate removed, it is held in place with a spot weld in each corner. I will weld it back in place after I have finished along the cut edges. Next is a view of some rot I have to remove. The last image is a general view of the workshop facilities. Thanks for looking and as ever all comments welcome David

-

Hi All I see its nearly 4 weeks since I updated, this not due to a lack of progress although I have not been able to spend as much time on 49 as I would like. As the years pass a warm fireside seems more preferable to a cold garage these days. However I have finished the passenger side front floor pan, I found 2 areas of rot which I cut out and butt welded patches into. No photos sorry, they were simply too similar to the rear pan repairs. I have now painted the passenger side floor pans which now look great and will help motivate me to progress the driver’s side. I hope to have the floors finished for very early in the new year. We are hoping to show the car and give passenger rides on the rally stage at Raceretro in February next year. https://www.raceretro.com/ I have also taken the time to bring the brake pipes and in particular the fuel pipes up to the latest MSA standards and at the same time renewing the fire extinguisher system which now has to be plumbed in and use tanks that can be serviced every 2 years. I am getting down to the last few period photos that I have and would love to know of any others that may exist. Thanks for looking David

-

Hi Simon How is FAV Yes it would be a good idea to list where what parts are available. I got the inner and outer rear arch panels from here https://www.carz2.co.uk/skoda-favorit-89-95-16519-c.asp They were good to deal with the parts I ordered were in stock and delivered in days. Front wings are available here https://www.centralpanels.co.uk/product/skoda-favorit-1989-1995-new-front-wing-l-h-fav1-231/ I haven’t used them and cannot comment on quality or service. An acquaintance of a friend is restoring an original 1960s Felicia and goes to Czech for parts a couple of times a year. Before his last trip we asked him to see if rear floor pans were available in Czech, he returned with a pair for £8.00 each. Next time he goes we will be asking for front floor pans and the chassis rails that are under the front pans. We don’t know if they are available but we suspect that they are. With google translate to translate your searches into Czech opens up a whole new world of Favorit parts availability. I am part of a group of Favorit owners between us we own 3 rally Favs so we tend to buy any panels we come across. New or good second hand. Hope this helps David

-

-

Hi All Do they say that power is nothing without control? Having got the rear passenger side floor pan as straight as it needs to be and all the tears repaired it was time to move onto the front pan. So firstly the front door was removed so I now own a 3 door Favorit…….. The door removal revealed a previously sheared bolt in the lower hinge plate that will need extracting. Fortunately a small stub remains so it should come out OK with a bit of weld and a nut. The first photo attempts to show the damage to the area of the floor above the chassis rail that is positioned behind the rear wishbone mounting. The chassis rail had been pushed up taking the floor with it. So out with my port-a-power, a ratchet strap and a piece of 6 by 6 timber I made a DIY jig, I was able to use the cage to push off, I would not recommend using the screen opening on a car without a cage. Judging by the ominous crunching I suspect the chassis rail will need some more repairs, however it already needed some from its previous brushes with the passing road. The second and third photos show the jig arrangement. The last photo fails to convey that I have moved the floor down somewhere between 30 and 40mm. It also shows how much of the “rust” was removed with my trusty CIF. Thanks for looking David

-

Hi All With the rear wheel arch now finished I moved on to the floor pans, seemed logical to start with the passenger rear one, it saved having to moving the tools very far…… So onward and upwards. The pan looked awful, with what seemed like loads of rust and any paint left being very discoloured, however a quick rub with a cloth moved some rust revealing paint. A dawn raid into the kitchen gained some CIF multi surface cleaner with lemon smell which I applied and left to soak for 10 mins. Removing with a sponge and plenty of clean water removed loads of mud and most of the discolouring. I did this before removing the brake pipes and fuel pipes do did not get everywhere clean. The red arrows on the first picture point to un cleaned areas the green arrows point to the 2 areas that had tears in the metal. The pan was surfaced rusted but not holed from corrosion. The first repair piece had been fitted when this photo was taken. A second application of the CIF cleaned the remainder of the dirt. The second photo is the badly battered piece of the floor I removed and replaced as shown in the photo above. As stated previously I am not fighting rot here it is the more easily repaired dents and tears from the battering the floors have received in the past. Removal of this piece allowed this area to be panel beaten back to shape more easily. Another view of the repaired piece fitted near the seat mounting. Due to the way the competition seat is mounted further back than standard the square box section, shown with the blue arrow above, forms the rear seat mounting. Whilst I am not the greatest welder in the world the photos don’t do my welding any favours. I have tried to get more representative photos of the welding but without success. I went out to check my welding when I downloaded the pictures from my phone I couldn’t believe how awful it looked. The photos shown in previous posts were in fact from the 1995 RAC Rally. This last photo is also from that rally. Thanks for looking David

-

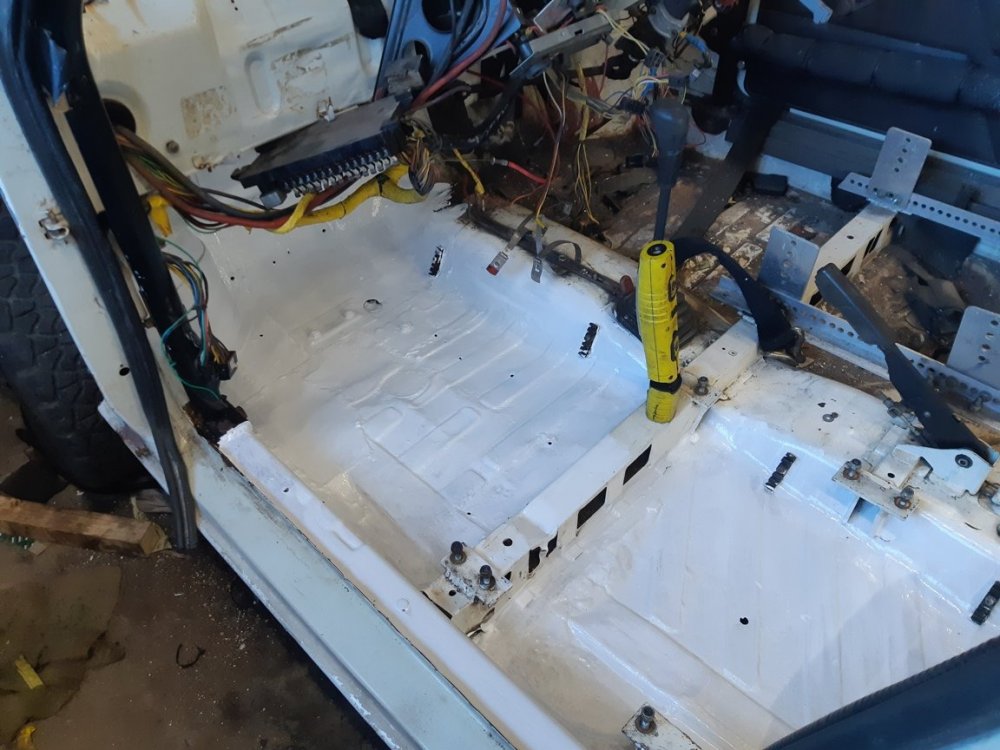

Hi All I finally got the motivation to weld the last repair piece into the rear quarter tonight, I think there is another hours welding and tidying then I can call it finished. Because I didn’t feel like welding last night I started on the next part of the project which is cleaning and de-rusting the cabin. The brake pipes and fuel pipes also need tidying along with sorting the fire extinguishers. I took the front screen out (it was cracked when we bought the car) to give me easier access to take the dash out. I am glad the screen was cracked and needed replacing because it disintegrated into fairly large shards of glass that I am sure should have remained stuck to the plastic layer in the middle. I wouldn’t like to have been involved in an accident with that screen fitted and been showered with all that glass. Whilst I will still have some holes to repair in the floors, but by this weekend the shell should be ready for the outside painting which will be a huge step forward. The painting is planned to happen as soon as possible. The photos tonight are a general view of the interior, a close up of the repair piece mid cleanup. Thanks for looking David

-

Thanks for your replies guys, its good to know my posts are reasonably interesting. All attempts involved CAD, the problem was a lack of the required skills to form the shapes in metal........ Anyway the part spent the day de rusting in some cider vinegar which I find works very well, I welded it up tonight and will flap wheel it smooth when I get a new flap wheel tomorrow. Then weld it in place. Now that I can move on from the outside bodywork I can make a start on the floor pans which are quite battered but only have a couple of tears and splits. As far as I can see so far there is surface rust a plenty But NO ROT so a bit more welding perhaps the odd panel to be let in and it will be a proper job. Cheers David

-

Hi All I spent the afternoon trying to get the quarter panel finished, it keeps fighting…….. I got the last of the welding of the arch repair panels finished, leaving just the final little last piece to recreate. Unfortunately this little piece is not included with the repair panels I had bought. I had 3 attempts to try and create it, the many compound curves always defeating me. Finally I decided to try incorporating the reasonably solid part of the arch curve, which I had only cut out to gain access to the cill top repair panel that I remade the other night, see the first photo below. Using this piece lead me into making the repair piece in several parts, rather like a 3D jigsaw, which then proved far easier than all my previous attempts. I now just need to weld it all together on the bench, dress it up, de rust it, weld through primer it and then finally weld it in place. It will need some filler to make it look acceptable but not much more than a thin skim. The other pictures show the repairs needed in this area. Thanks for looking and comments and discussion is very welcome David

-

I find its just a case of taking small steps, yes if you worried about all the areas at once it could become daunting. I just break things down into small jobs, however in this case the quarter is proving to be a lot of work. I try to spend an hour every night after work, long enough to see progress but short enough to not get bogged down. I also find it helps to have several mini projects on the go so if I didn't fancy welding tonight I have something else to progress. However I started to weld the outer arch panel tonight a slow process to avoid warped panels and not photogenic but its looking good in the flesh. AND PROGRESS Finally keep your dream in mind it will be as good as you hope one day. Cheers David

-

Hi All So with more gas bought it was again time for some welding. Firstly I finished welding the arch lip from Saturday. Next I trimmed the repair panel to perfectly fit the areas of the outer arch or quarter panel which I have had to cut out. I also cut this outer repair panel into 2 halves, I hope that this will greatly ease fitting time will tell. The photos tonight document the fitting of a repair piece to the rear end of the cill where it had corroded again due to a lack of paint when previously repaired. The first 4 pictures are taken during the cill repair. The last photo is from happier times. Thanks for looking David

-

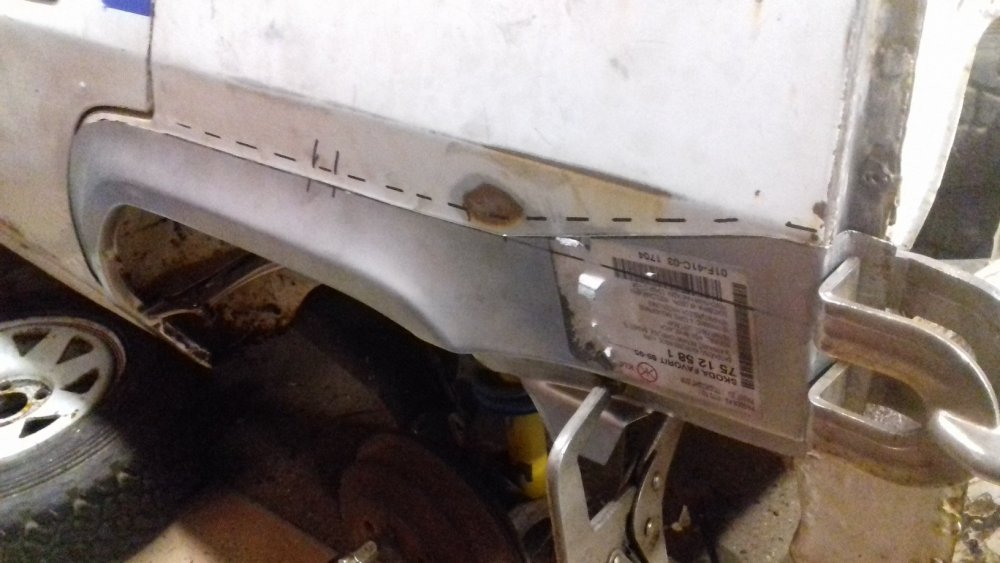

Hi All I spent a productive afternoon on bodywork repairs to the Favorit. I made little plates to fit and fill the old redundant bonnet pin holes, tack welded them in and added a little filler to level the repairs. I also made new spare wheel well bungs and welded them in. The originals were missing. Sorry I forgot to take any interesting pictures of these 2 jobs. I spent the rest of the afternoon repairing fully the inner arch lip where I cut it back due to rot. I trimmed the repair panel to fit my needs and then very nearly got it welded in. I failed due to a lack of gas. So with the inner lips position now fixed I started to trim the outer repair panel again to fit my needs, I do not need or want to fit the entire panel. The first three photos are with the bumper fitted back to see how everything lines up. I was very happy with how close everything fitted. This is after all a cover panel so I did have to reduce the rear flange standout. I will also have be creative around the door opening. The forth photo is after I had started to reduce the outer repair panel's size. Sorry for the repeated use of the same camera angle witch is not even a good angle but I am restricted by my garage's dimensions. The final photo is the start of the Kerridge Rally from I think 1994. Thanks for looking and please feel free to comment.