-

Posts

63 -

Joined

-

Last visited

Profile Information

-

Location

Havana, Cuba

Car Info

-

Model

Skoda Estelle

Recent Profile Visitors

964 profile views

Aram's Achievements

-

Thank you guys, I really appreciate it but it turned out I just sold the Estelle. Not in my plans, but a guy got severely in love with the engine and the work I was doing, so in love he accepted a price figure I told him, ridiculously high like x4 the real value just to get rid of him He actually "burned" my phone calling me to sic' me for the sale. He said he had never seen a rebuilt like this and took the car even with the rear in the floor. Made me an offer I couldn't refu$$e hehehe. So...I'm about to get into yet another adventure soon, a winzip'ed "car" or like I say, a bike-with-a-wig: Fiat 125P heheheh...but this Skoda is gone.

-

Well it cranked...but didn't go well: I got a lot of grayish smoke, oil being burned? If that's the case, perhaps, since I can't have original rings so the ones I put are "made". Oh well, I see I will need to tear it down again and check stuff. I could visually inspect inside the cambers through the spark plug holes, there is oil there. I wonder are the rings, or I went too happy oiling the chambers while building the engine. When I did a little crank without water, just to check it starts, I could see this kind of little smoke out of the thermostat casing and the water pump. I guess it would be paint, oil, etc being fried. I put hoses to the engine and the out hose into a bucket, I didn't got bubbles there. I guess compression is not going into water system, right? Also: sparks 1, 2 and 3 are slightly oily. Spark 4 started to get black burn So what could be? Rings? Bad carb settings (too rich)?

-

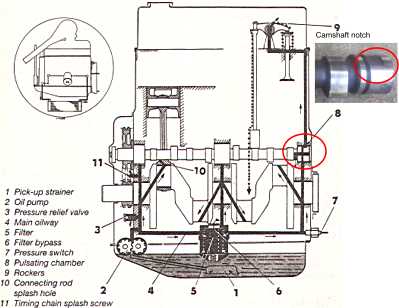

Today's work: checking oil pressure I freaked out at first because the rockers were not getting any oil...the camshaft position was preventing oil going up there. So turned the engine to BDC and the oil flow improved a lot: in Haynes book then I see they call this "pulsating chamber", so it seems it acts like a valve so closing/opening would increase oil pressure, so it gets into the head by bursts. Even more: this explains why the filter gasket (old) wasn't holding and I could get oil pressure being blowing like if I opened a disturbed soda can! Since now the engine is all clean/revamped, oil pressure is good and the weak point was the old gasket. I made a new one, worked.

-

The engine came with a Lada carburetor. It is something quite normal here...they adapt such carbs to almost any engine. I have even seen "modern" fuel injection engines with their fuel system removed and a Lada carb installed, mainly because lack of new parts. As for cutting the bakelite plate in halves: first, I trace cut lines in the sides with permanent marker... simple stuff: lay the marker over the table, adding or removing paper sheets below it to adjust its tip height, then rotate the plate over the table but not over the sheets, rubbing the side to mark against the pen tip. That guarantees that the line is marked evenly in all the sides. Then put the thing in the vice and using the jigsaw mark well those lines by slow, short and precise moves. Once the sides are well marked, start sawing a few strokes, then rotate the part again and again. It is like if the bakelite was to have a round inner cut. Once it is cut, obviously it won't be precise enough so I attach a thick sand paper like 30, 40, 50 grits over a flat surface, secure it with masking tape, then sand the cutted side again like when cutting, a few strokes back and forward, then rotate the piece and again and again, checking with a caliper and against a piece of glass. Sounds like tremendous work but a. needs to be done, so no excuses and b. t is enjoyable, specially when it is done.

-

Oh it "needs" to work at the end unless it turns to be so ungrateful. I'm almost done with the engine. In fact I only need to clean the alternator and massage the carb...but as the carb was working ok, I may clean it after a first run, to to avoid adding yet another failing point if I mess with its regulation. I guess I should first try to crank it, then if all went well, clean the carb. But before that I will fabricate a support mount for the starter so I don't need to hook the massive gearbox just for the starter. And do a proper test stand.