-

Posts

386 -

Joined

-

Last visited

-

Days Won

1

R_Blue last won the day on 3 August 2021

R_Blue had the most liked content!

Profile Information

-

Interests

Keep the car rolling.

-

Location

ALT + 0138 = Š

Car Info

-

Model

Škoda Forman LX - W/LPG

-

Year

1993

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

R_Blue's Achievements

-

tuning Tuning Carburator 1.3 Felicia

R_Blue replied to Camera's topic in Skoda Favorit, Skoda Felicia, Skoda Fun and Skoda Forman

- 22 replies

-

- 1.3 carburator

- 1.3 8v

-

(and 1 more)

Tagged with:

-

R_Blue started following Koni Street rebuilt. , My Felicia has a broken windshield wiper , Anyone looking for a Skoda Pickup in the east of england? and 2 others

-

I checked local stores and rear wiper motor for Felly is not available. You are lucky to still be able to find it locally. (Thanks to @Thefeliciahacker ) Think like this; if it served 20 years, a new one will serve at least 20 years more. If this happened 5 years later, maybe you wouldn't be able to find a new one at that time. I'd say, buy a new one. Keep the old one. You can have it repaired and sell it later or keep it for spare parts. Especially for the gears inside.

-

Škoda Favorit 1.9 TDI

R_Blue replied to R_Blue's topic in Skoda Favorit, Skoda Felicia, Skoda Fun and Skoda Forman

I'd like to know that too. -

Tuning Carburator 1.3 Felicia

R_Blue replied to Camera's topic in Skoda Favorit, Skoda Felicia, Skoda Fun and Skoda Forman

It can be done but how long will it last? Isn't that the crack case breather?- 22 replies

-

- 1.3 carburator

- 1.3 8v

-

(and 1 more)

Tagged with:

-

Tuning Carburator 1.3 Felicia

R_Blue replied to Camera's topic in Skoda Favorit, Skoda Felicia, Skoda Fun and Skoda Forman

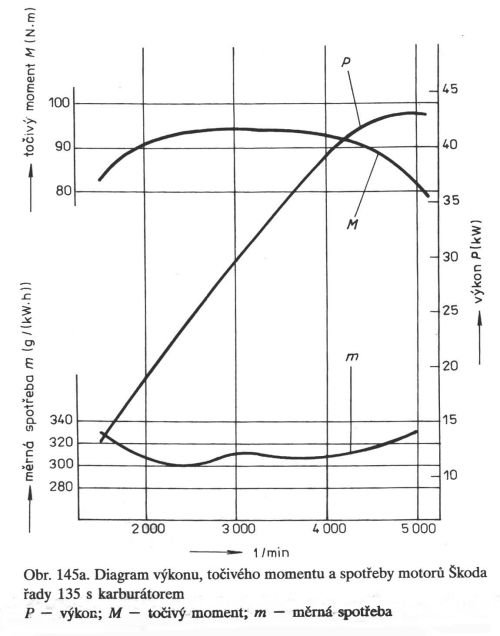

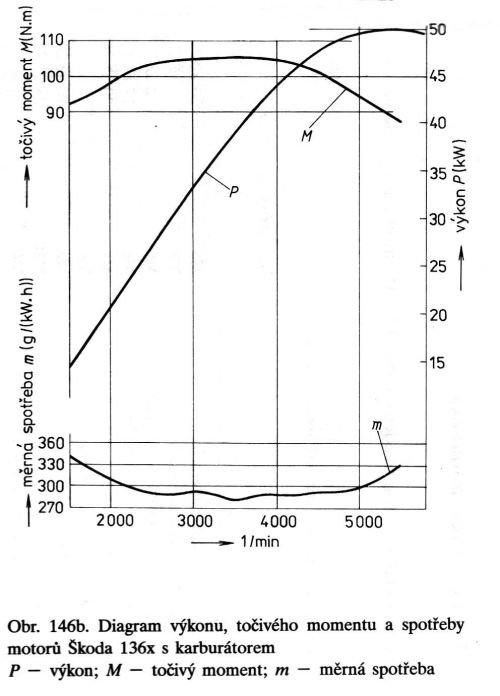

We are on the same boat. As a carburetor 1.3 owner like you, I did lots lots of search and brainstorming for increasing power without too much compromise and fit it in a budget. Fist of all, I agree with @nta16 about doing prerequisites on the car, before beginning engine work. For engine upgrade, one must think logical way which includes basic HP formula. Power (W) = Torque (N.m) ∙ Speed (rpm) / 9.5488 Maybe all of us heard that before, there are two important characteristics for an ICE. Torque and total power. But if you look at formula, to understand how the total power is calculated, it says: "How powerful can you rotate and how fast can you do it?" So, to increase total power, according to formula, we need either increase torque or have the engine capable of running faster. Or both. Now, lets analyze what we have first: These curves are our engines' characteristics. 135, 136 and 136X respectively. One must understand that, when ICEs are designed, everything is optimized for ideal running conditions for the meant purpose. Especially the rpm. This includes, cylinder configuration and dimension, burning chamber design, valve dimensions and numbers, detailed valve timing, intake and exhaust manifolds. Everything sums up to achieve the curves you see above. If you look carefully, you will notice that, an ICE is not very flexible about efficiency. For 135 and 136 engines the most efficient rpm is around 2500. With 136X it's around 3500rpm. 136X is the most sporty version from factory. It has different cam. While 135 and 136 have same cam but different compression ratios. Comparing the 135 and 136 curves, you can understand how increasing the compression effects engine characteristics. Comparing 136 and 136X shows, effects of cam modification. (Both 136 and 136X have same high compression) Increasing compression ratio is a no-brainer if you have a 135 engine. Which was meant for old times where high octane fuel not available everywhere. As you can see from the charts, increasing compression ratio does not change the general shape of the curves nor change the target operation rpm range a lot. But changing cam, basically shifts optimized rpm range! Engine is more efficient @3500 rather than 2500. Power is rated at 5500 instead of 5000. As you can see, when you speed up the engine beyond a level, it loses sync. Torque drops dramatically. That's because of fixed values like cam profile, valve timing etc. Because of losing torque at high rpms, turning the engine faster does not yield more total power. It's just fuel waste. If you read upon this point, now the question is, can we make the engine more efficient at higher rpms by changing cam, intake and exhaust modifications etc? The answer is yes but the more aggressive cams you use and the more you tune for higher rpms, the more you will lose low rpm idle capability. You end up getting a smooth idle at 1000rpm for example. Instead of 800. Thus, affecting drive-ability and fuel consumption in the city. How other cars can rev higher rpms? There are advanced technologies like variable cam profiles and variable valve timing devices. For example; Here comes the mighty Honda VTEC. https://en.wikipedia.org/wiki/Honda_Civic_Type_R Civic Type R EK9 With the engine B16B DOHC VTEC. 182HP @8200rpm 160nm @7500rpm From a 1.6L engine. One the highest output per liter engine ever built. VTEC adjusts valve timing on the fly, based on engine rpm. It's almost tuning itself based on your need. Marvelous isn't it? Second question is, can our engines withstand higher RPMs? For reliable long term operation, the simple answer is NO. Škoda 1.3 Engine is not designed for high rpms. First of all our engine has three main bearings. Instead of five. This helps saving fuel because of lower friction, but it's not good for high rpm stability. Our engine is not cross-flow. Limiting airflow speed in the engine. 8V OHV. Pushrod design. Good for durability but very bad for achieving high rpm. Beyond a level, all mechanical parts chained together in a pushrod system goes out of sync easily. There is a problem with oil pump worm gear lubrication happens at high rpm. Head gasket reliability is a concern on every modification for this engine. From my personal experience, sustained operation beyond 3500rpm accelerates valve clearance adjustment go off. You end up doing it more often. Here is my chain of thoughts about modification with pros, cons and hard walls. 1- 136X conversion. Adopting high comp pistons is OK. No problem. Just plug and play. Special cam needed. 136X cam is the same with pre-98 Felicia 136 MPI. From what I heard, it has different journal. It won't fit without modification. Special made cam needed. Where can I find cam profile data? Hard wall: Original 136X has a different distributor! With a different centrifugal advance setting! Very hard to replicate. If it's done correctly, you get 50KW. Instead of 46KW. (Compared to 136 engine) Worth it? (If I travel intercity, I usually go exactly at 3500rpm @ 5th gear. But, I don't go intercity everyday. Instead of that, I use the car in the city everyday between 2000-3000 ranges. So normal cam with 135 and 136 engines is more suited for city driving) 2- Weber DCOE conversion with custom intake manifold and reworked exhaust system. With lots of engine characteristics and tuning mentioned above, another important issue about engines is the drive-ability and usability. This includes cold starting and flawless operation in very cold weather. When you consider this, other important bits of the engine design comes into play. Standard carb. Jikov 28-30 LEKR, which is a Pierburg 2E3 clone has an automatic choke. I personally tried and tested. Even at -18ºC it can start the engine with one crank. Standard intake manifold has coolant supply and placed very closely to the exhaust manifold. You will lose all of this with Weber DCOE. I know DCOE has its own cold start mechanisms but I don't know if they are as effective as the standard setup of our cars. It's a race carburetor and race teams start and heat their engines before the race. Heated intake manifold helps the gasoline evaporate and mix better with the air. Other than that, weber DCOE and custom intake manifold conversion is common with small volume engines. One can find many samples through VW Golf Mk.1/2 forums. Extensive data can be found about choosing right carburetor dimensions and jets. For example: https://www.carbparts.eu/calculator Chinese clones of DCOE are available for very low prices too. In the end, intake manifold and exhaust system must be done with precise calculations. At the end of building the system, final adjustments of the carburetor(s) must be done with Dyno runs. Like I wrote before, DCOE conversion is only done for increasing air-flow efficiency. We can't increase the engine speed too much. In the era of carbs. very few cars had side-draft carbs installed from factory. Here is a fine example: Alfa Romeo Giulietta from 1954 https://en.wikipedia.org/wiki/Alfa_Romeo_Giulietta_(1954) It has the same 1.3 engine configured with different compression ratios and different types of carbs. See the engine variations in the wiki page. This is a twincam engine. VERY advanced for its time. 3- Bike carbs. conversion. Needs custom intake manifold like DCOE conversion described above. For our engine, I think Honda CBR 600 carb. is suitable. I couldn't find anyone who did that for our engine. So anyone who attempts to make this happen will be doing the honors of discovering all the tuning needs, pros and cons. Fuel pressure regulation, lots of jet adjustments and Dyno runs needed. I don't know how it idles or cold starts. Just like DCOE conversion, this is done for increasing air-flow efficiency. 3- Forced induction We can't increase max rpm so how about increasing the torque? 3a- Turbo First of all, with a head gasket reliability problem engine, increasing the cylinder pressure is not a good idea. But if we use low comp piston set and keep the pressure very limited we may have a chance. Even if you do all the welding and piping work of turbo, the hard wall here is; carburetor itself. Even at stock, Pierburg 2E3 is very sensitive. It is not compatible to force feeding. Force feeding capable specially built carbs are available in US. But they are for their huge V8 engines. Not suitable for our cars. Theoretically you need a pressure chamber built around the carb. with controlled fuel pressure. Imagine how it would be to tune the jets inside the carb. Also turbo is good for higher rpms. Not good for our engine. We need pressure at low down 2000-3500 range. 3b- Supercharger This is more suitable for our engine. It will provide steady pressure at low rpms but same handicaps applies here too as with the turbo. Having carb. makes the project almost impossible. There are small and cheap superchargers on the market by the way. But don't forget, you have to install intercooler too. To wrap it all, all forced induction solutions are actually easier if you convert to custom ECU and MPI. That means buying the custom ECU, all the sensors it needs, replacing flywheel with position sensor compatible one and installing all required sensors, including lambda accordingly. After building the forced induction system, an expert ECU programmer engineer who works with Dyno is needed. To prevent the engine to blow. Correct ECU programming is critical. If you don't know someone who can program an ecu from ground, with little to no previous data, don't attempt this project. What is the most you can get without compromising too much reliability? Between 80-90Hp I think. Calculating all the costs of the project, does it worth it? I don't think so. Here is something for you from my info cache: http://www.mm.pl/~miazio/HistoriaTurbo.pdf The author did this for a school project or something like that. It includes many details about the nature of the job. He used a Garrett GT15 from an Astra 1.7TD. The car has custom ECU. He is not declaring power as a solid data. He doesn't have intercooler or blow-off valve. ------ GEARBOX!!! ----- Let's don't forget about the gearbox. It plays a great role in fuel efficiency and drive-ability. Gearbox ratios are chosen based on engine torque, speed and vehicle weight. Basically, gearbox must match the engine curves above. Any modification you do, you may end up with gearbox not matching the end result. You may be happy with very short gears and very fast acceleration in each gear but it will drink fuel. Up to this point, what I learned, engines are designed from ground to achieve a specific workload scenario. Tuning further is all about exploiting the leftover potential. IF there is any in a particular engine. For our engine, it is designed to achieve city based drive-ability in mind with maximum fuel efficiency and minimum build cost. We can't drift away the engine from it's fundamental purpose a lot. It doesn't have a lot of potential. So what can be done? When browsing Czech sources, I learned that there was a company who built custom made liner and pistons to increase the volume of the engine reliably. Nothing beats volume right? If I remember correctly, they increased to even 1.6. If they are still operational a trip to Czech Republic is needed. With correct jets our standard carbs can run on 1.6 too. Other than that, my personal advise is making mild modifications without altering the base engineering of the engine too much. If you had the MPI from the beginning, I'd advise what @D.FYLAKTOS did. Small modifications to the chip. With custom exhaust. I think he had 70-75HP. Best of both worlds. Close to stock, yet more powerful. @Thefeliciahacker can calculate exhaust dimensions too. 4- 135 to 136 conversion If you have 135 engine DO IT! The cheapest and easiest of all modifications for carb 1.3 Škoda. This engine had been engineered for 9.7 compression ratio. The low comp(8.8) pistons are for being able to use poor quality gasoline. Which is not a case anymore. Increasing compression ratio to 9.7 provides everything! More efficient engine, more torque, more power! According to Škoda tech-web cz, it is safe to increase the ratio further to 10.5 and using 95 octane fuel. I think this will give close to 68HP even without the cam modification. In the hot summer days, standard cooling system may not provide adequate cooling. So better radiator needed. Don't forget to port the intake and exhaust manifold. They are very crude. Proper polishing technique must be chosen and applied by an expert though. 5- Switching to MPI One can discuss reliability of carb vs MPI injection system. Once properly adjusted, carb runs without issues. As a rule of thumb, the more parts in a system means, the more chance for any of those parts to go bad. But carb is not better than ECU driven MPI system. Because MPI uses many more actively monitored variables to adjust engine parameters. Simply switching to MPI will yield more power without any cold start, bad idle etc. issues. Standard Felicia 136 MPI is rated for 68HP. That's with CAT and worse exhaust than Fav. Without CAT, I think it will easily give +70HP. All parts are available for converting a carb. 1.3 engine to MPI but we still have one problem. The cam shaft. One must make absolutely clear if the correct cam fits to the block available. Because 50KW standard ecu will not work properly with a different cam profile. The best practice could be, switching to MPI with custom ECU. Just like computers. Comparing a PC from 1996 with one from 2016. A modern ECU is a lot faster than Škoda's stock one. That means, with compatible modern sensors, sampling rate will be higher and ECU will make more corrections per second. But again, the price will be high and an ECU expert is needed. So, if nothing works, we came to the ultimate conclusion. 6- ENGINE SWAP Many owners decided to go this way because of the mentioned reasons above and also the cost and gain ratio. With the gearbox adapter from Felica 1.6, you have a wide range of engines available from VW but, the most favored ones are AFH and AVY. 1.4 16V 100HP and 1.6 16V 125HP respectively. With the necessary bits sorted out, you get guaranteed factory tuned solid power. Here is a recent swap example. Honestly, I'd do the same if I could. Footnote: Please remember, I'm not an expert in engine tuning. I'm just a simple user. What I have written above might include some mistakes. I hope, if there is any, others read and correct them. Cheers.- 22 replies

-

- 3

-

-

-

- 1.3 carburator

- 1.3 8v

-

(and 1 more)

Tagged with:

-

Škoda Favorit 1.9 TDI

R_Blue replied to R_Blue's topic in Skoda Favorit, Skoda Felicia, Skoda Fun and Skoda Forman

So if it was a PD engine it could end up like: (Not because of those crashes but x3.2 of designed torque) 😀 But, it's good to see Favorits are still getting some attention for engine swaps. I hope the author on youtube completes their project and posts more videos about it. -

Škoda Favorit 1.9 TDI

R_Blue replied to R_Blue's topic in Skoda Favorit, Skoda Felicia, Skoda Fun and Skoda Forman

@Papez How about this one? https://www.ultimatespecs.com/car-specs/Volkswagen/3111/Volkswagen-Golf-4-TDI-150.html 320Nm @ 1900rpm 😱 I can't recognize which engine they used but, can Favorit handle that much torque? -

Koni Street rebuilt.

R_Blue replied to D.FYLAKTOS's topic in Skoda Favorit, Skoda Felicia, Skoda Fun and Skoda Forman

When I see a suspension lowering topic, the first question comes to my mind; if the mentioned car has skid plate or not. When the suspension is lowered, the risk of hitting vital components of the car to obstacles or ground imperfections increase. Especially the gearbox. I have a heavy shield installed and I'm glad I have that. One time at winter when following a truck, a frozen snow slush ice cube had suddenly fallen. It was big. I think it merely cleared the front bumper but I hit the damn thing with 70Km/h with a loud bang. The skid plate took the impact. Sport cars, especially the ones with lowered suspension need underside protection if the car is meant to be driven outside of track use. -

Ignition barrel wiring favorit

R_Blue replied to Wezzlers's topic in Skoda Favorit, Skoda Felicia, Skoda Fun and Skoda Forman

In my pics and the OP's the wires look red. After looking carefully, I think among @Wezzlers's cables, there are two lighter tone reds. -

Ignition barrel wiring favorit

R_Blue replied to Wezzlers's topic in Skoda Favorit, Skoda Felicia, Skoda Fun and Skoda Forman

More visualized version. No:30: Two terminals. Black + Red crimped together in one connector. Black is Battery (+). Red is side light switch. Second terminal is reserved for stereo. No:50: One terminal. Yellow. Starter motor connection. P: not connected. No:15 Two terminals. One black goes to fuse/relay box. Another black goes to ignition module & coil feed. (Unfused! Design flaw?) (In my previous pictures above, the second connector is hidden. Probably the extra black cable you were asking is this. Your stereo may be connected from a ring connector bolted on fusebox.) No:16 One terminal. Two red cables crimped in one connector. One red is from the low level warning switch of the brake fluid reservoir. The second red is from instrument cluster brake light bulb. -

Ignition barrel wiring favorit

R_Blue replied to Wezzlers's topic in Skoda Favorit, Skoda Felicia, Skoda Fun and Skoda Forman

Your car is from April '91 but you have a new type fusebox. Reminder: Please disconnect the battery terminal (-) before working on ignition barrel. As you can see, there is unfused direct connection from battery here. -

Ignition barrel wiring favorit

R_Blue replied to Wezzlers's topic in Skoda Favorit, Skoda Felicia, Skoda Fun and Skoda Forman

Here you are: https://www.mediafire.com/file/8u046dj57o9gvgg/electric_system.zip/file This link can be deleted. Please download and keep it for further reference. @RicardoM and @Thefeliciahacker may find this useful too. Also, It makes me sad to see what a dirty thief did to your Fav. I'm glad they couldn't take it.

.thumb.jpg.7f7967fb2bfe220b9c418160abc42158.jpg)